rockwell hardness test brass|how to calculate rockwell hardness : exporters Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for Dragon Age: Inquisition - The Epic Action RPG - On PC, PS4 and Xbox One - EA Official. A cataclysmic event plunges the land of Thedas into turmoil. Dragons darken the sky, casting a shadow over lands on the .

{plog:ftitle_list}

webVeja resultado jogo do bicho Paraíba 10 horas, jogo do bicho Paraíba 12 horas, jogo do bicho Paraíba 14 horas, jogo do bicho Paraiba 18 hora, jogo do bicho Paraiba 16 horas e jogo do bicho Paraiba 20 horas. Na Resultado Fácil você confere o Resultado do Jogo do Bicho de hoje e de ontem da LOTEP e Paratodos Paraíba. Acompanhe os .

understanding rockwell hardness scale

Standard industry hardness testing methods, including Rockwell, Brinell, or Vickers, will suffice for brass. However, the testing method often requires a hardness testing machine with an indenter with the application of known loads to cause a depression on the . A Rockwell hardness tester. The Rockwell scale is a hardness scale .

typical rockwell hardness of materials

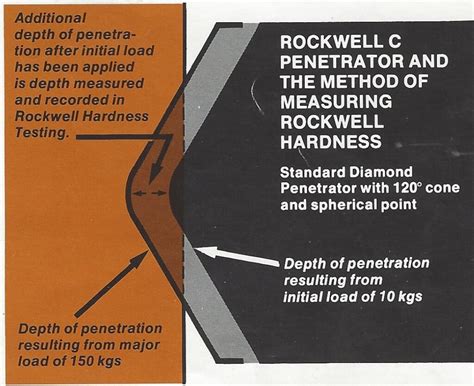

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Sheet metal may be too thin and soft to test on a given Rockwell scale without exceeding the minimum thickness .

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.

Hardness of Brass. Brinell hardness of cartridge brass – UNS C26000 is approximately 100 MPa. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major . Rockwell Hardness Standard Test. The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of .

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

rockwell hardness test chart

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .Bring material right to your bench to measure its hardness. These testers use a carbide indenter to take accurate Rockwell hardness readings every time. They come with a calibration certificate traceable to NIST that states they’ve passed a test for accuracy. With a durable metal body, these testers stand up to many environments, from heat treat facilities to workshops to .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .An indenter with a hard metal ball or a cone/diamond pyramid is pressed vertically into the surface of the test specimen resting on a solid support. The test load is applied impact-free with . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0 .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . The Rockwell hardness test is divided .

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Rockwell B scale (RHB): This scale is used for testing harder materials, such as brass, mild .

Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is employing the correct hardness testing method to show .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . For example, “HRC 96” for a metal means the hardness of that metal is 96 when .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for . Brinell hardness. The Brinell hardness scale is a widely accepted measure of hardness in materials. It involves pressing a ball of steel (or tungsten carbide for harder materials) into the test piece at a constant and known force. The softer the material, the deeper the ball will penetrate and vice versa. The next step is to take a measurement of the diameter .

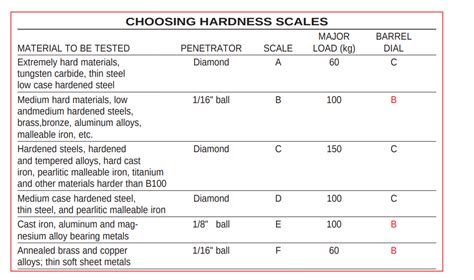

12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load.Examples of items that can be tested range from ballistic shield panels to small springs. Applied Technical Services uses many common testing standards including ASTM E10, E18, A370, E384, E92, A956, A370, ISO 6506-1, 6507-2, EN ISO 9015-2, EN 1043–1, and 1043–2.

There are several types of indentation hardness tests, including Brinell hardness, Rockwell hardness, Vickers hardness, and micro-hardness, which differ in terms of the indenter used, the applied load, and the duration of the load. ③ Rebound hardness. Rebound hardness testing is primarily used for metal materials. Rockwell hardness testing machine. . This can be related to the fact that tensile strength is proportional to the hardness of the metal following the equation [16]. UTS HB (4.1) . The test procedure for the Rockwell hardness test is covered in the standard document ISO 6508 for metallic materials and ISO 2039-2 for plastics. The overall procedure is similar to other indentation tests. . The Rockwell hardness number (B) for brass lies in the range of 55 to 93 depending upon the composition of the alloy. Cartridge brass .Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

donatelli hip drop test

Figure 1. An operator performing a Rockwell hardness test. (Source: Arkansas Department of Transportation.) The Rockwell hardness is calculated using the following formula: Rockwell Hardness, HRC = [0.2 – permanent depth of indentation (mm)] x 500. The Rockwell hardness test was developed to be less destructive and cheaper than the Brinell test.

rockwell c hardness scale examples

rockwell c hardness scale chart

how to calculate rockwell hardness

web31 de mar. de 2023 · MARI ÁVILA ( COMPLETO DELA E MAIS 200 MODELOS LINK NOS COMENTÁRIOS ) GRUPO NO TELEGRAM AS MELHORES E FAMOSAS MODELOS .

rockwell hardness test brass|how to calculate rockwell hardness